Automakers around the world are taking measures to fight against the Covid-19 aka Coronavirus by building equipment that can be used by the medical staff.

General Motors is also playing a big role during this crisis, for example, is using its sheer size and muscle to help a company called Ventec build up to 200,000 of its ventilators, using GM’s purchasing power and factories.

It claims it has 95 percent of the parts needed to push the project forward, but others aren’t due to ship until April and beyond.

General Motors is also playing a big role during this crisis, for example, is using its sheer size and muscle to help a company called Ventec build up to 200,000 of its ventilators, using GM’s purchasing power and factories.

It claims it has 95 percent of the parts needed to push the project forward, but others aren’t due to ship until April and beyond.

Tesla’s Elon Musk a week back decided to import 1255 ventilators from China and shipped the first batch to New York and Los Angles. Andrew Cuomo, New York governor says the city grateful and itself needs 60,000 units with the escalating situation. That’s just one city in a country of 325 million people. Hence, 1255 ventilators are not enough. Musk has also sent some 50,000 3M-made N95 surgical masks to the University of Washington’s Medical Center.

Earlier this month, Mr. Musk pledged to reopen Tesla’s gigafactory in Buffalo, New York – which builds solar cells. But given the current situation, he has decided to repurpose it to manufacture additional ventilators.

“Giga New York will reopen for ventilator production as soon as humanly possible. We will do anything in our power to help the citizens of New York,” he wrote on Twitter.

Tesla’s Elon Musk a week back decided to import 1255 ventilators from China and shipped the first batch to New York and Los Angles. Andrew Cuomo, New York governor says the city grateful and itself needs 60,000 units with the escalating situation. That’s just one city in a country of 325 million people. Hence, 1255 ventilators are not enough. Musk has also sent some 50,000 3M-made N95 surgical masks to the University of Washington’s Medical Center.

Earlier this month, Mr. Musk pledged to reopen Tesla’s gigafactory in Buffalo, New York – which builds solar cells. But given the current situation, he has decided to repurpose it to manufacture additional ventilators.

“Giga New York will reopen for ventilator production as soon as humanly possible. We will do anything in our power to help the citizens of New York,” he wrote on Twitter.

Ford

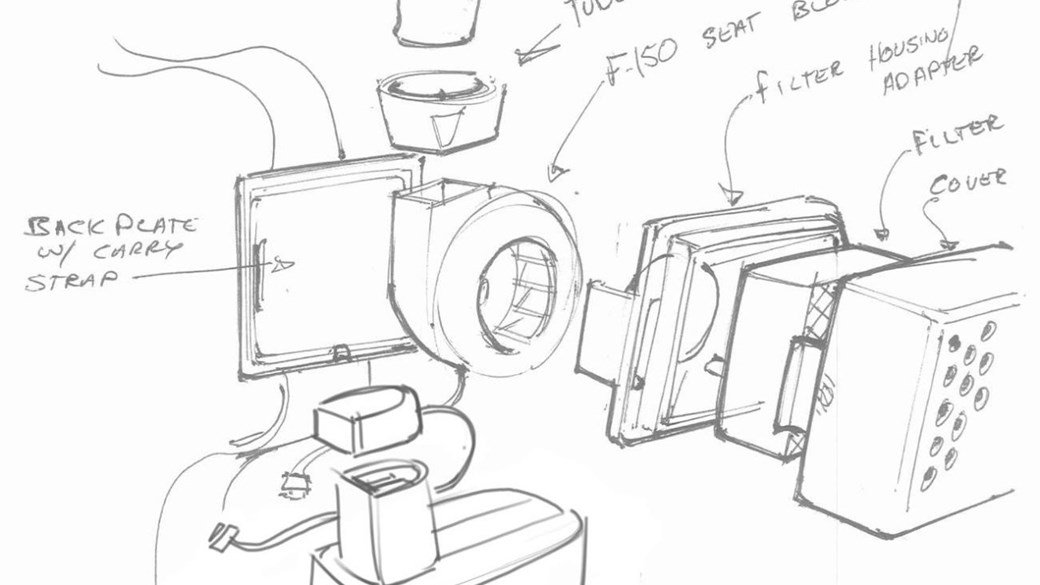

Ford’s is working with 3M and General Electric to build ventilators and masks that could be used by health workers who are tending to sick patients with coronavirus. Some of these plans are roughly sketched out but it gives you an idea. To assemble this design, parts such as a seat blower fan, plastic backing plate and a brace of tubes powered by a drill battery can be used. While the drawings came together in a few days, a viable ventilator product won’t likely surface until early May.Why the delay?

It’s not the fans, obviously. Ford can whistle up enough fans from a supply chain that can sell more than 2400 every single day in the US. Hoses and seals are easy to attain however the delay comes in the area of electronics. Outside suppliers will need to design and test the right parts, before manufacturing the complete unit at the facility With every plant standing idle, there is plenty of manpower to build them. Furthermore, a typical car factory has enough space that can be used as a clean room for assembling. The capacity to print 3D parts at scale is also a big advantage. Several people are not at work at the moment due to the coronavirus precautionary measure. Hence, it’s easy to see where delays and bottlenecks might occur before completion. Additionally, units will need to be prototyped and tested before sent out.General Motors

General Motors is also playing a big role during this crisis, for example, is using its sheer size and muscle to help a company called Ventec build up to 200,000 of its ventilators, using GM’s purchasing power and factories.

It claims it has 95 percent of the parts needed to push the project forward, but others aren’t due to ship until April and beyond.

General Motors is also playing a big role during this crisis, for example, is using its sheer size and muscle to help a company called Ventec build up to 200,000 of its ventilators, using GM’s purchasing power and factories.

It claims it has 95 percent of the parts needed to push the project forward, but others aren’t due to ship until April and beyond.

Tesla

Tesla’s Elon Musk a week back decided to import 1255 ventilators from China and shipped the first batch to New York and Los Angles. Andrew Cuomo, New York governor says the city grateful and itself needs 60,000 units with the escalating situation. That’s just one city in a country of 325 million people. Hence, 1255 ventilators are not enough. Musk has also sent some 50,000 3M-made N95 surgical masks to the University of Washington’s Medical Center.

Earlier this month, Mr. Musk pledged to reopen Tesla’s gigafactory in Buffalo, New York – which builds solar cells. But given the current situation, he has decided to repurpose it to manufacture additional ventilators.

“Giga New York will reopen for ventilator production as soon as humanly possible. We will do anything in our power to help the citizens of New York,” he wrote on Twitter.

Tesla’s Elon Musk a week back decided to import 1255 ventilators from China and shipped the first batch to New York and Los Angles. Andrew Cuomo, New York governor says the city grateful and itself needs 60,000 units with the escalating situation. That’s just one city in a country of 325 million people. Hence, 1255 ventilators are not enough. Musk has also sent some 50,000 3M-made N95 surgical masks to the University of Washington’s Medical Center.

Earlier this month, Mr. Musk pledged to reopen Tesla’s gigafactory in Buffalo, New York – which builds solar cells. But given the current situation, he has decided to repurpose it to manufacture additional ventilators.

“Giga New York will reopen for ventilator production as soon as humanly possible. We will do anything in our power to help the citizens of New York,” he wrote on Twitter.

Medtronic

Medtronic, US-based company that is specialized in making ventilators has pushed its output from 100 to 225 units a week but needs to source 1500 parts from 14 different locations for each one, in a time when logistics management is a huge challenge. The production of a ventilator may sound simple but essentially the device is used for pumping oxygen and removing carbon dioxide from sick patients’ lungs. With the shortage, even though ventilator makers have doubled their output, these would not be manufactured in time. Hopefully, with the combined efforts of Ford, GM, Tesla and many more in partnership with GE Healthcare, we can make this process quicker.-

Performance - /10

0/10

-

Driving Pleasure - /10

0/10

-

Look and Style - /10

0/10

-

Fuel Economy - /10

0/10

-

Value for Money - /10

0/10